In Mumbai, the nerve centre of the business & Commercial capital of India, LIBESH ENGINEERING WORKS WORKS commenced their Mould Manufacturing Unit in the year 1994. Shri Suresh Babu, the young dynamic entrepreneur confidently and whole heartedly ventured into mould related Hot Runner System in 2004, with terrific success. Libesh has many reputed & famous clients in Mumbai, all over India and in many locations worldwide.

A hot runner contains a series of channels that distribute molten plastic within a mould. Mould with hot runner system deliver moulded components with uniform destiny free from runner, more economically and faster.

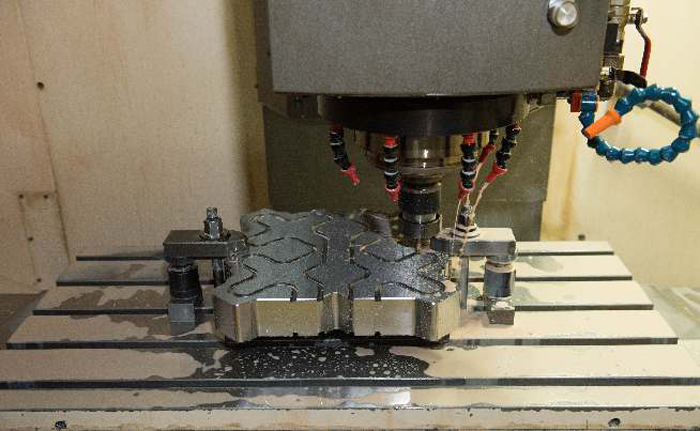

LIBESH ENGINEERING WORKS has in depth knowledge of good mould making and hot runner technology. These two combined experience of more than 22 years, but libesh at a superior position to serve the industry better than most other campanies.

Libesh engineers have deep knowledge and experience in design & manufacture of high cavitation system which are fully balanced. Libesh manufactures reliable, high performance hot runner for which they are able to provide maintenance service & technical support wherever and whenever as the necessity arise.

Libesh’s expertise increases overall efficiency, clearance parts & measurable results and improves the quality of the moulded plastic products. Clients get increased production output and reduce operational cost, make the unit generate more profit. Hot runner use 100% VIRGIN MATERIAL, NOT PROCESSED RAW MATERIAL OR RE-GROUND MATERIAL hence better quality plastic assurance in 100% certain.

A hot runner contains a series of channels that distribute molten plastic within the mould, unlike a cold runner mould. The plastic in the mould never freezes. Thus the production cycle is faster, get less rejections and better finish . The Hot runners substantially reduce production cost per shift and saves on plastics and energy bills. It gives uninterrupted production and is more economical for the large quantity production jobs and also for large size moulded parts where volume exists. Libesh’s experience enables them, to build moulds with gates so closely positioned as to yield better, faster quality moulded parts.

Manufactures widest range of Quality hot runner system at very competitive price and is a more reliable supplier too. Libesh possess high technological also practical knowledge & provides appropriate technical support to the customers.

We have the superior technology and our Engineers & technician are highly experienced make superior; quality hot runner system.

Its contains individual hot tip nozzle and is fully automatic with a capacity of up to 40 cavity mould. Advantages/ Benefits of Hot Runner Systems

A more reliable better quality and quantity production of parts-No finishing work required on end product.

Saving in material cost-no runner to grind or reprocess. Shorter, faster cycle time-no runners to cool and also eliminate nozzle freeze problems.

Can use lesser gramege machines for the same job. Automated productions-need not Separate Automated Productions-need not separate runners from moulded parts.

Gates at better positions-economical in desigining reduces contamination possibilities.

Uniform heat within cavities leads shorter ejection time. Easy availability of space parts & components-standard

Its contains one drop for two cavity and is applicable for multiple cavity upto 60 cavity mould.

Wearing parts available ex-stock, less production interruption. Easy color change.

Availability of standard nozzles.Consistency in moulded parts because of easy filling by heating elements.

Applications to Single & Multi-product moulds. Smooth Gate marks. And gate marks of 0.8 mm. Greater availability of abrasive & aggressive materials internally, externally or internally/externally heated and controlled single or multiple cavity nozzle international quality and standard.